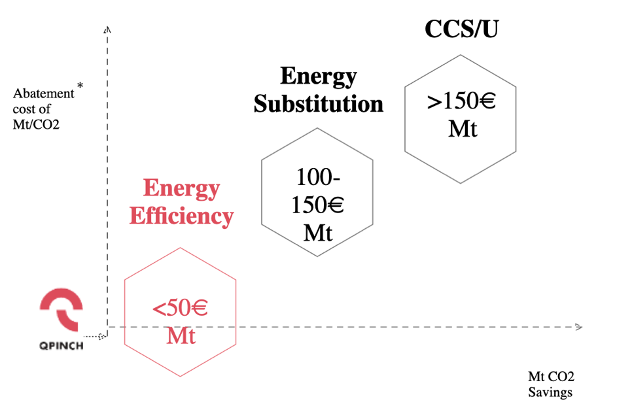

Far left on the abatement curve

There is huge untapped potential in waste heat recovery and energy efficiency for the innovators. Read some Qpinch insights on why the abatement curve matters.

Table of Contents

- Energy efficiency (EE)

- Timing and yields

Let’s cut the waffle. Environmental policies have been voted on and they are being enforced, putting augmented pressures on (petro)chemical industries. No C-level executive or ops manager is waiting passively for emission abatement targets to magically manifest themselves. Many have smart energy substitution plans and intricate carbon capturing & storage (CCS) roadmaps in place to deploy the vast infrastructural changes that need to be made to many of our industries. But there is huge untapped potential for the innovators.

Industry leaders have long recognised the energy transition as a deeply disruptive shift. For the petchem industry this quickly turned into a race to see the last man standing. Since the abatement curve has become a pivotal matrix in our interpretation of the end goals, we are now craving technology that is ideally placed in its vector field. You’ve got it: on the far left and down by the x-axis. All current industry strategizing appears to be welling from that source. It feels crucial to continuity and even industry survival.

Energy efficiency (EE)

In bona fide Sun Tzu tradition, it is even more important now to take a step back, observe the arena and dissolve some of its complexity. One strategy includes exploiting undervalued advantages. Energy efficiency is an oft overlooked component in the game plan of abatement optimization. All planned energy substitution and CCS investments are in direct correlation to the estimated future requirements of process energy. So, it’s obvious to look at maximising energy performance and make every MW work to its full potential.

That is where Qpinch and our QHT (Qpinch Heat Transformer) technology come into view. Massive amounts of a considered byproduct are now expelled into the environment. Qpinch exploits the idle capacity of waste heat through recovery and transformation (GHG emission reduction - Scope 1). QHT installations are non-invasive (close to zero process downtime), low maintenance, have very low electricity consumption and are built with readily available and standardised parts. Resulting in double digit percentage efficiency improvements and positive cash flows that are dropping Qpinch’s activities below the x-axis of the abatement curve. Exactly, into the profitable returns, on top of those immediate CO2 emission savings.

QHT technology is an easily adaptable add-on to most existing plant infrastructure that can be introduced in various process departments, leading to a +20% plant energy saving potential. Making it the most meaningful and cheapest circular waste heat technology available for producing useful industrial steam. Far outperforming voluminous heat pumps and steam compressors, in terms of energy yield, financial savings, CO2 savings, plot size and implementation timelines.

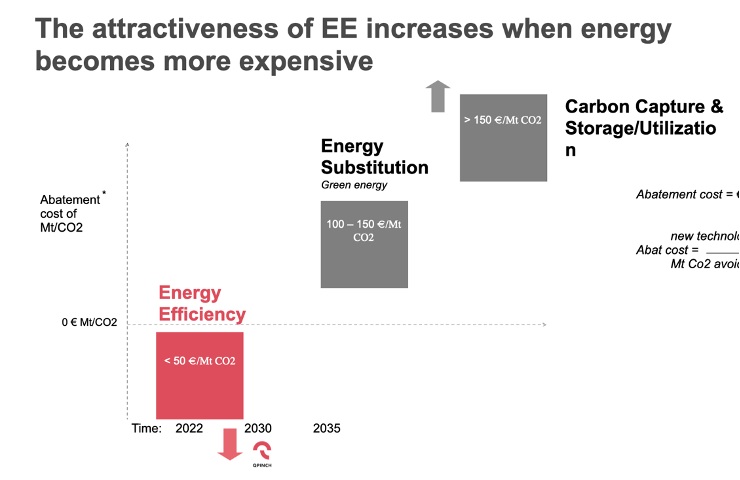

Timing and yields

Let’s briefly discuss timelines. Energy substitution and CCS installations will take decades to install and become functional. The focus there is on emission reduction potential. But the costs are steep and business value creation will be in the negative, as professed by their positioning on the abatement curve.

QHT technology is available today and promises a short implementation track, with faster CO2 emission reductions and positive internal rates of return. But also offering extra value creation in the wake of energy or CO2 price increases.

Improving plant energy efficiency converts into savings, waiting to be harvested.