Technology

The Qpinch Heat Transformer

See the fundamentals of our Qpinch Heat Transformer explained. We are engineers and well versed to answer any specialized questions you may have.

The QHT: Qpinch Heat Transformer.

Introducing the Qpinch Heat Transformer: A breakthrough chemical heat pump that converts waste heat into carbon neutral industrial heat. This is a physico-chemical installation for medium to large scale (>10MW) applications, making it suitable for implementation across all processing industries, often in various departments. The add-on design of the units enables easy numbering up when capacity increases are needed.

Thanks to our QHT we can offer countless energy efficiency opportunities, across all industries.

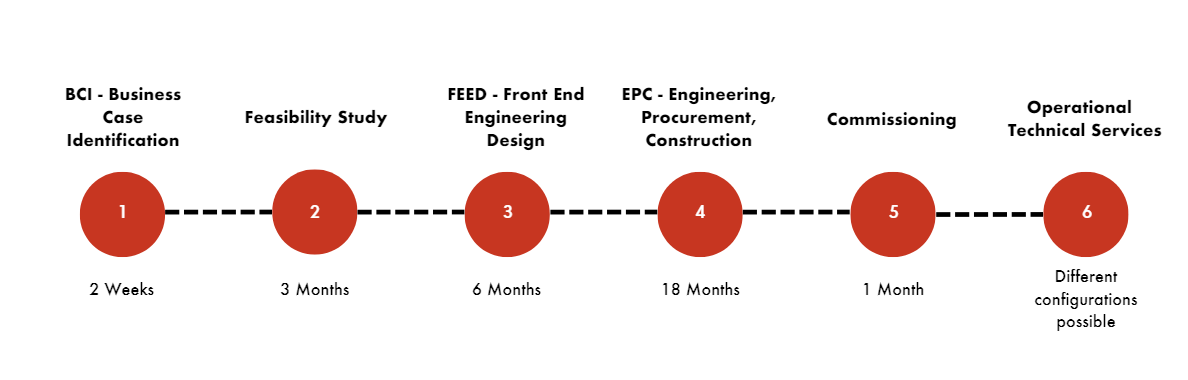

The Qpinch project flow

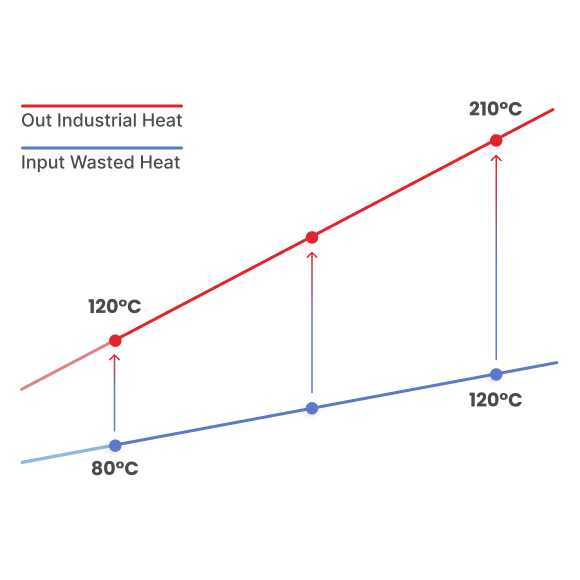

Big temperature jumps in one single step

QHT optimal operating parameters

°C min

The bottom temperature at which the phosphoric acid inside the QHT can absorb waste heat.

°C lift

Minimal temperature lift capacity between absorbed waste heat and produced carbon neutral process heat.

% max

Your maximum OpEx of electricity is 4% of the delivered output, resulting in a COP of 25.

°C max

The maximum achievable process heat temperature, equivalent to CO2 neutral steam of 18 bar G.

MW

The smallest standardised QHT unit has a nominal steam production of 0.5MW absorbing waste heat from hot water.

MW

The biggest customised QHT unit designed and approved by our engineers to date, provides 15MW process heat production.

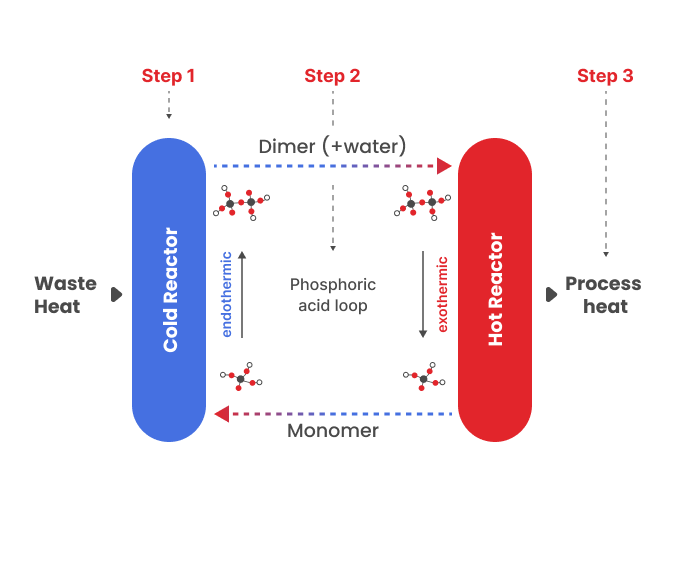

It’s elementary: converting waste heat into industrial process heat

Capturing waste heat

Steam, hot liquid and vapours contain a lot of residual energy that is now released in the atmosphere – either directly or via cooling. The QHT can absorb waste heat down to 80 °C.

Transforming waste heat

The captured low temperature waste heat is transformed into high temperature process heat, using a physicochemical reaction. No electricity is needed to drive the temperature lift.

Delivering New Energy

We recover 50% of your residual heat and transform it into new process heat with temperatures of up to 210 °C. Our technology is applicable on megawatt scale.

Convert your waste heat to process heat with Qpinch

The bulk of process heat in the Oil & Chemical industries lies between 120 and 220°C. Waste heat starts at 150°C all the

way down to ambient temperature. Roughly speaking, many plants have large amounts of waste heat at 120°C and below,

even after having exploited its potential to further raise the efficiency of their processes.

Refining

Increase your energy efficiency reusing waste heat

Aside from the attractive financials, Qpinch offers solid operational benefits to help you reach your decarbonisation targets without taxing your functional continuity. Our QHT is innovative technology that can be efficiently integrated on any site. Find out more about the actual implementation process.

Minimal maintenance

A QHT installation is built with industry standard components and uses no rotating parts or compressors, making the installation highly efficient, with low-maintenance requirements.

Safety compliance & sustainability

All industries we serve have strict safety regulations, which our project teams are well equipped and trained to handle. QHT is safe and proven technology, with 14 years of R&D and without chemical consumption or use of expensive catalysts.

Modular & flexible Tech

The QHT can cope with a wide range of heat fluctuations, both in duty and temperature, with limited need for operator intervention. The modular design allows for the combination of multiple heat sources and swift capacity expansion by numbering or scaling up.

Low OpEx - high yield

The combination of marginal electricity requirements and low-maintenance demands of the QHT installation, results in the most efficient process steam output per euro spent: 40kW of electricity per MW steam.

A breakthrough inspired by nature